3D Design and Digital Field Measures for Glass Railings (Balustrades), Staircases and other glass applications

Bent glass balustrades perfectly measured with digital precision

Bent glass balustrades and other specialty glass is no longer hampered by the need to measure, manufacture, transport and store cumbersome and time consuming physical templates.

With Glasshape on-site digital measurement service, our specialist technicians visit your site, with state-of-the-art scanning hardware to produce a digital twin of the as-built structure with unmatched accuracy. The digital twin 3D CAD model is used as a reference to design our bespoke bent glass to, that can be reviewed and approved by the client ahead of production. This added layer of checks and balances means inaccurate measurements and human error are practically eliminated from the process.

In the event that at a later stage, a replacement piece of glass is required, we have the exact record of what was produced and can reproduce it precisely.

3D Digital Measures & Design Services

Want to view & receive a copy of our 3D Digital Measures & Design Services Brochure?

3D Digital Measures & Design Services

Want to view & receive a copy of our 3D Digital Measures & Design Services Brochure, Click on the Button below…

The Design Process

Glasshape has developed a tried and tested process of design through to production, which includes carefully considered stages to ensure we deliver the best possible product and service to our Customers.

The following list details the design process and provides approximate time frames, based on a typical project for each stage. These time frames can vary depending on the complexity of a project and the availability of quality design and field measure data, which is critical to ensure we develop the most accurate information possible, prior to committing to production.

Our highly skilled Engineers and Designers will work with you every step of the way, to ensure we deliver a premium product and service.

A. Receipt of Order & Job Creation

The Customer Experience Team to have an initial scope overview of the project with the Production Design Manager, liasing with the Customer on RFI’s as required.

B. Design & Site Preparation – Request Information

If a Field Measure is required, the Production Design Manager will liaise with the Customer on pre-measure prep details such as Site Plans, Photos, Site Access and Health & Safety requirements.

C. 3D Laser Scanning Field Measurements (Optional)

If required, Glasshape Technicians will undertake an onsite Survey using either Laser Scanning or other Digital Technology to gather critical information.

D. 2D & 3D CAD Modelling & Drawings

Referencing Customer supplied and site surveyed information, Design Technicians Reverse Model the As-Built Structure creating a Digital Twin, building in glass components to be manufactured, while identifying potential issues with the view to resolve prior to production.

E. Review Design With Customer

In the event that any issues are identified, the Production Design Manager will review the Modelled Data with the Customer to confirm details.

F. VR Immersive Design Review (Optional)

The option to review the 3D CAD Model using VR Technology in real time, is available upon request. Additional charges apply.

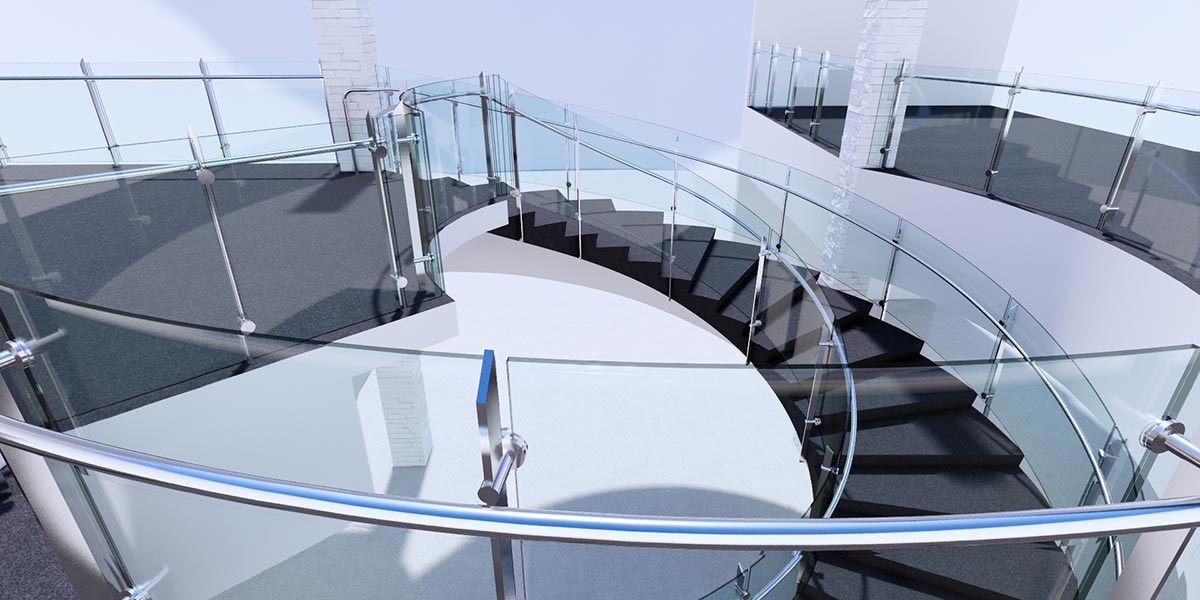

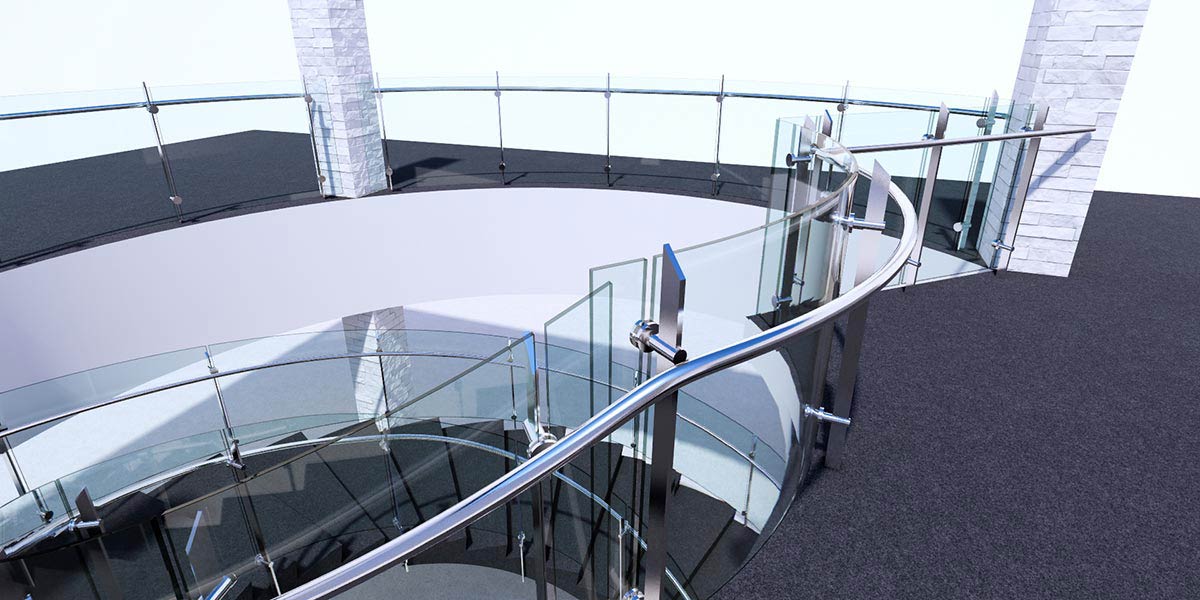

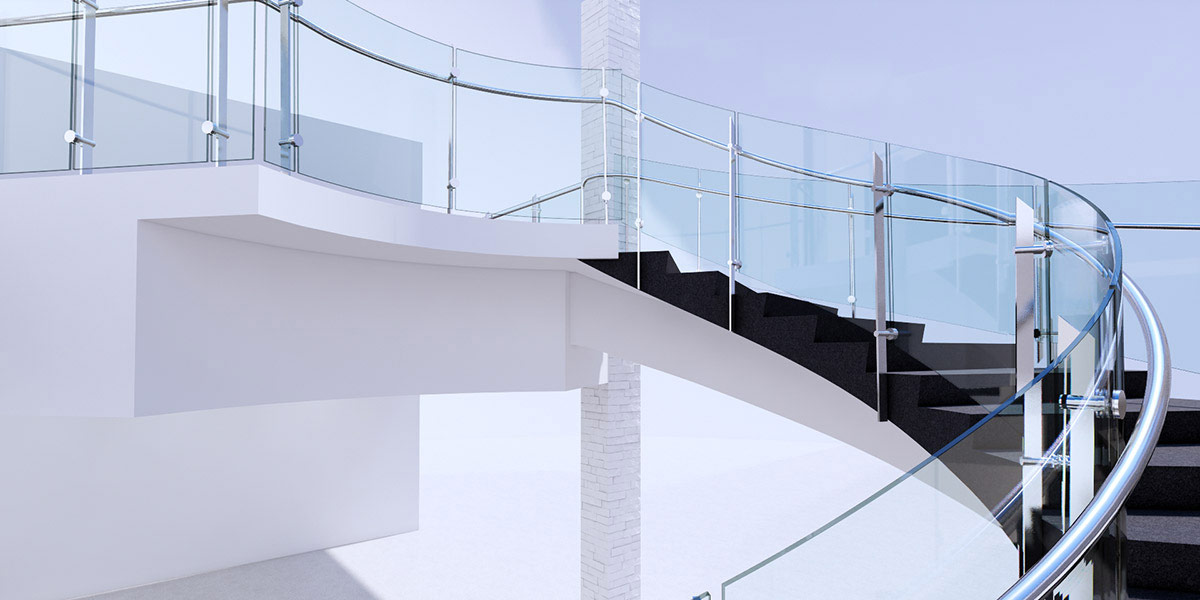

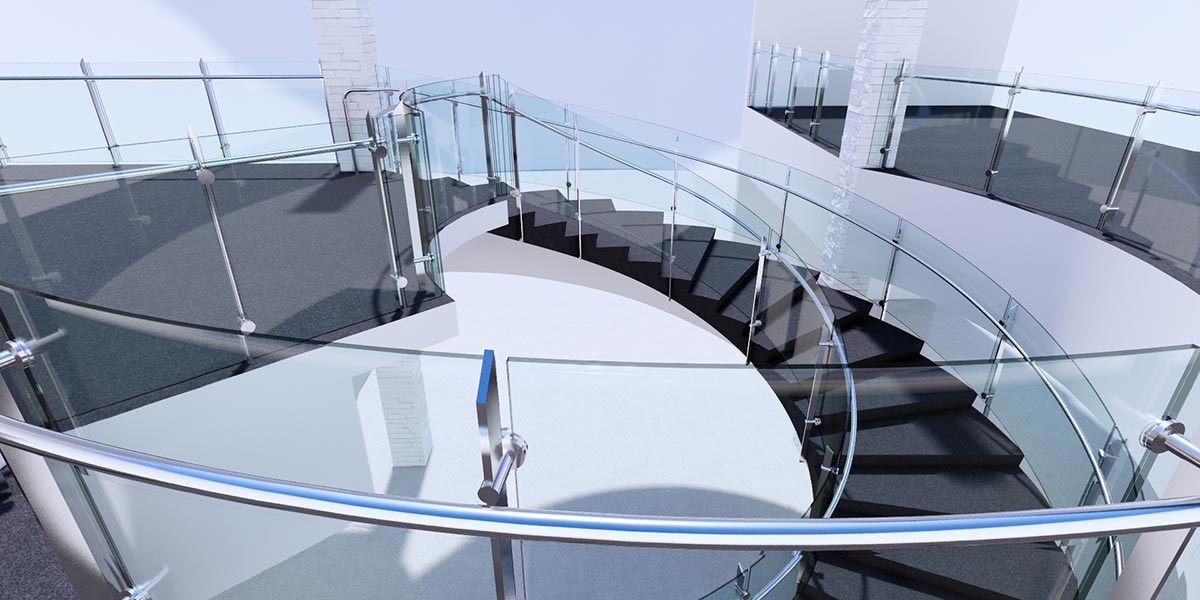

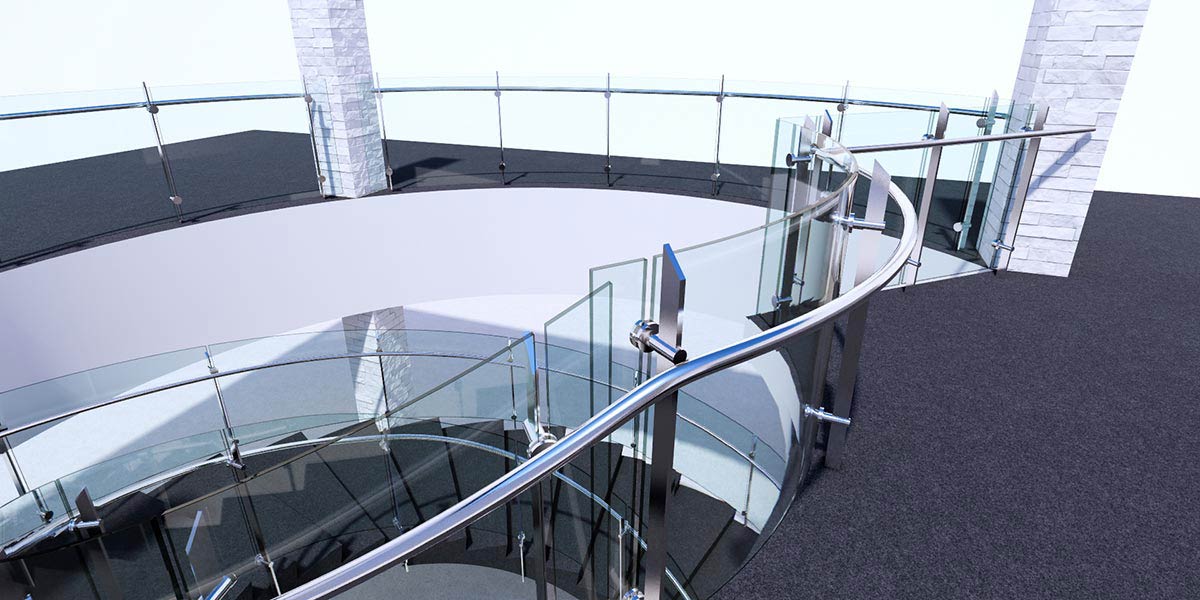

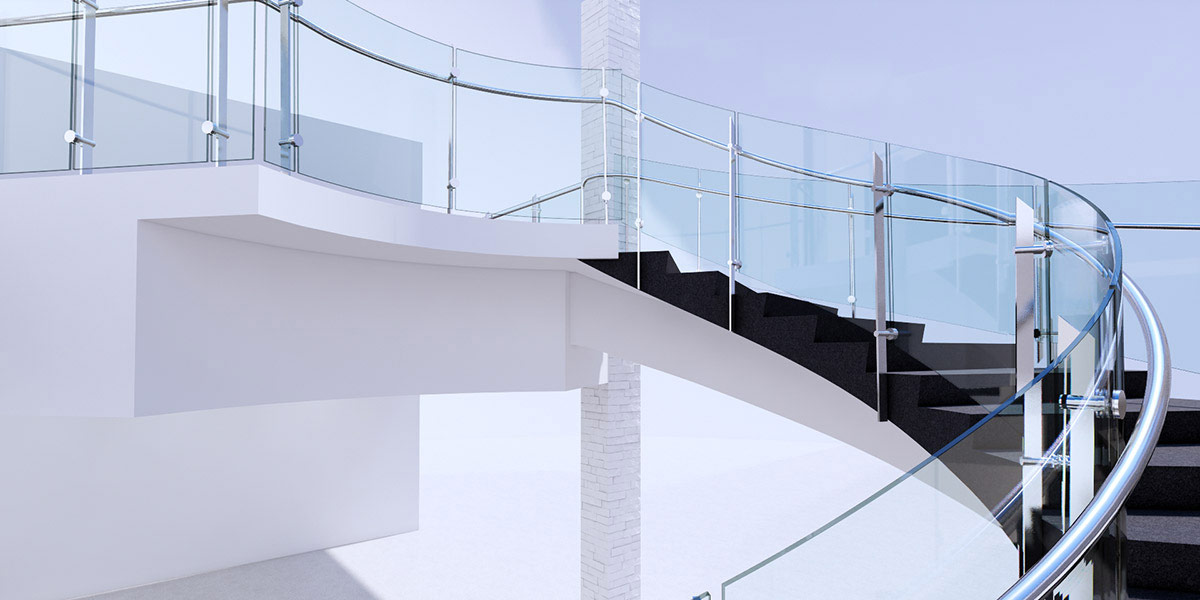

G. Photo Realistic Images & Animation (Optional)

Photo Realistic Images & Animation can be produced using the 3D CAD Model and are available on request. Additional charges apply.

H. 2D & 3D Drawings Sent To Customer

Final 2D Drawings and 3D Models are prepared and sent to the Customer for checking and approval, prior to Production commencing.

I. 2D & 3D Information For Production

Customer approved drawings sent through to Production for Scheduling Manufacture.

3D Digital Field Measures

Our digital field measure service utilizes the latest scanning and digitizing hardware to produce a digital twin of the as-built structure with unmatched accuracy, doing away with the need to produce cumbersome and time-consuming physical templates. The digital twin 3D CAD model is used as a reference to design our bespoke bent glass to, that can be reviewed and approved by the client ahead of production. This added layer of checks and balances means inaccurate measurements and human error are practically eliminated from the process.

Watch the “From Field Measure to Finished Product” Video

Video: Glasshape | Houston Stair Company

3D Virtual Reality - Design Reviews

Communicating and understanding design intent is critical when producing products that need to deliver on, or above customer expectations. To ensure this happens, Glasshape engages with its customers throughout the design process, resolving any potential issues before a single piece of Glass is manufactured.

Design reviews take place on-line in a Virtual World, using the latest VR Technology, where our CAD Technicians walk customers through their projects in real time.

3D Design Animations

Producing engaging Animations and Photo Realistic Renderings are also part of our Design Service offerings. If you would like to take your project with us to the next level and present it to your customers, then talk to our Sales Team and we will see what we can do for you.

Sapphire Lounge - LaGuardia Airport - N.Y.

Headlands Technologies - Chicago

Twin Helical Stairs - Georgia

High Roller Staircase - Las Vegas

French Fashion House - Sydney

Animations: Glasshape